Analysis Of The Current Situation And Development Trend Of China'S Cutting Tool Industry Market In 2020. The Degree Of Localization Is Expected To Improve

時間:2020/12/23 關(guān)鍵詞:YongPu Precision 瀏覽量:16898

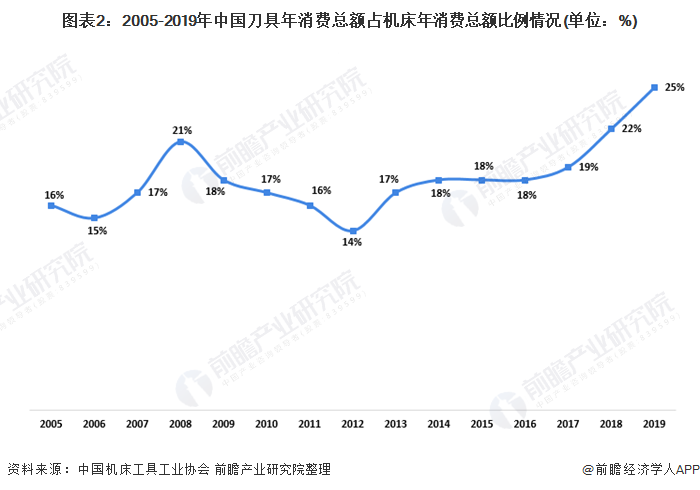

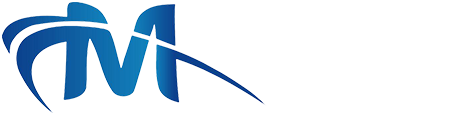

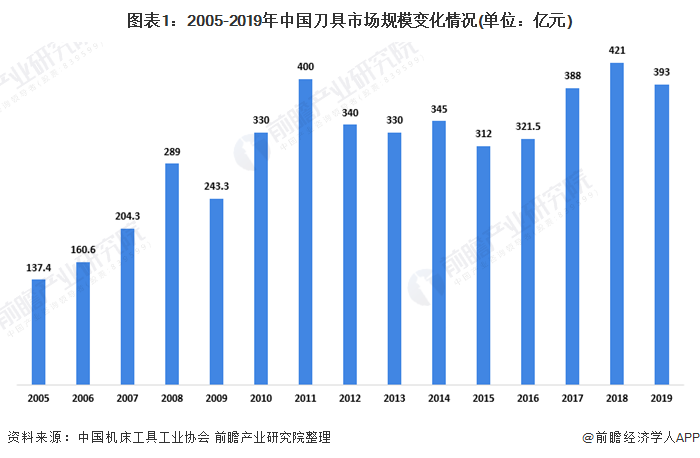

Due to the intensification of the Sino-US trade friction and the continuous decline of downstream industries such as automobiles in 2019, the consumption amount of cutting tools in China has declined. After 2012, the ratio of the total annual consumption of cutting tools to the total annual consumption of machine tools in China has shown an upward trend, reaching 25% in 2019, indicating that the consumption of tools in China is improving and upgrading, but it is still far below that of developed countries.

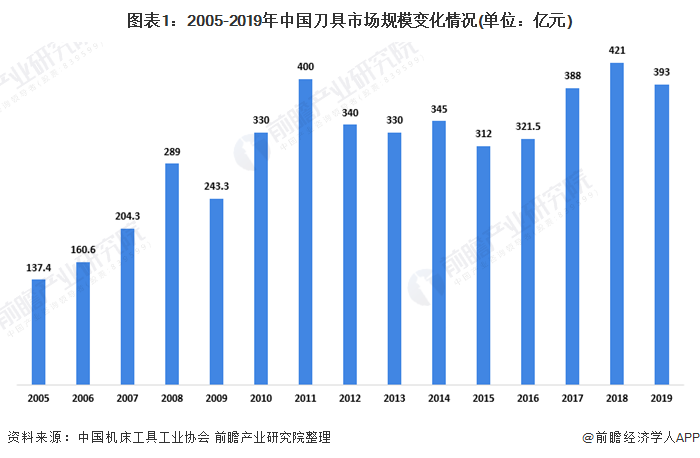

The total consumption of the domestic cutting tool market continues to rise

The consumption situation and structural changes in the cutting tool market are a barometer of the development of China's manufacturing industry. After experiencing fluctuations from 2012 to 2016, the total scale of China's cutting tools has rapidly developed towards automation and intelligence with the implementation of the "13th Five-Year Plan", and the transformation and upgrading of the manufacturing industry has promoted the rapid development of the cutting tool industry. From 2016 to 2018, China's cutting tool annual consumption scale showed a significant rapid growth, and the total annual consumption of cutting tools reached 42.1 billion yuan in 2018, exceeding the high point of 40 billion yuan in 2011, creating a historical record. In 2019, due to the intensification of Sino-US trade friction and the continuous decline of downstream industries such as automobiles, the consumption amount of cutting tools in China has declined.

China has been the world's largest consumer of machine tools for many years, but the consumption level of cutting tools is low. In developed countries such as Germany, the United States, and Japan, the law of modern CNC machine tools and CNC cutting tools coordinating and balancing each other's development is very obvious. According to statistics, the consumption of cutting tools in developed countries is about 50% of the consumption of machine tools. With the improvement of the management consciousness and technical strength of domestic enterprises, more and more enterprises have begun to invest in automated machining systems, and the consumption of CNC cutting tools has gradually increased. After 2012, the ratio of the total annual consumption of cutting tools in China to the total annual consumption of machine tools has shown an upward trend, reaching 25% in 2019, indicating that the consumption of tools in China is improving and upgrading, but it is still far below that of developed countries. It can be seen that there is still a lot of room for improvement in the consumption level of cutting tools in China.

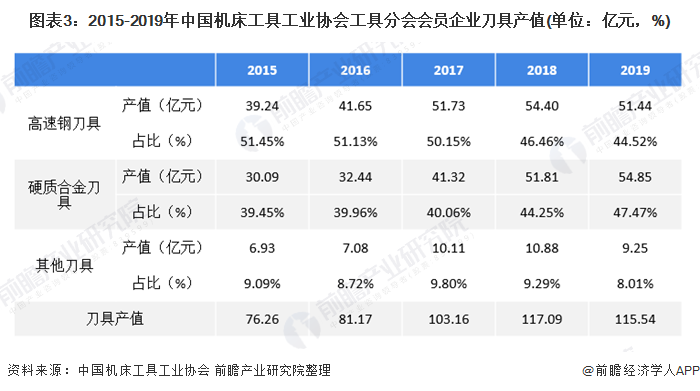

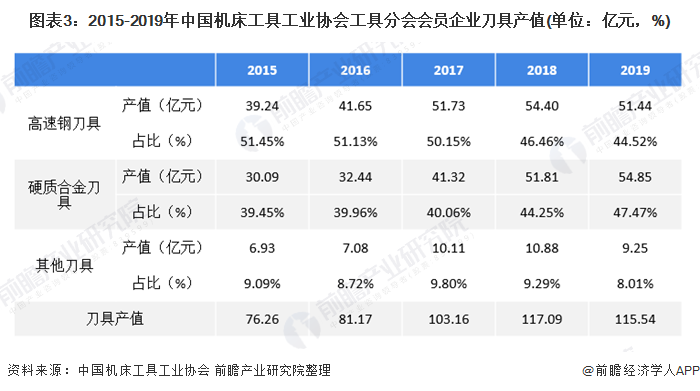

The value share of hard alloy cutting tools is gradually increasing

The change in the supply structure of cutting tool materials in China is related to the development level of China's manufacturing industry. In recent years, the value structure of cutting tools in China has been continuously changing, and the value share of hard alloy cutting tools with superior comprehensive performance has been continuously increasing. According to the statistical data of the Tool Branch of China Machine Tool and Tool Association, the value of hard alloy cutting tools produced by China's main cutting tool enterprises increased from 39% in 2015 to 47% in 2019. Hard alloy cutting tools are the leading cutting tools participating in digital manufacturing, and the increase in their value share is related to the macro background of the upgrading of China's machine tool equipment towards numerical control. In the future, as China's manufacturing industry continues to upgrade, the value share of hard alloy cutting tools will gradually increase.

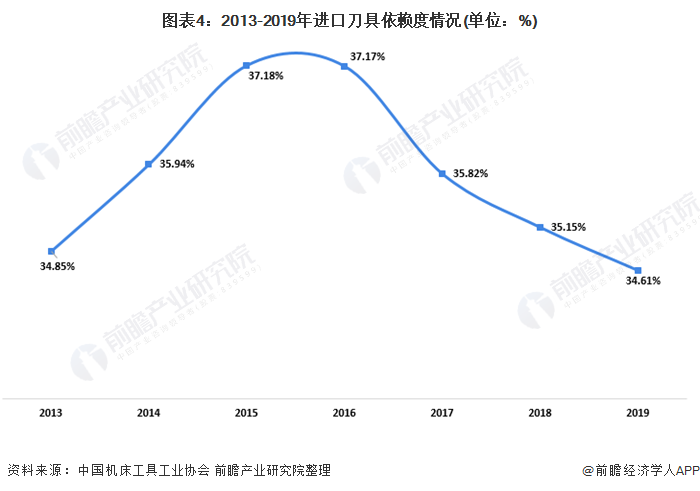

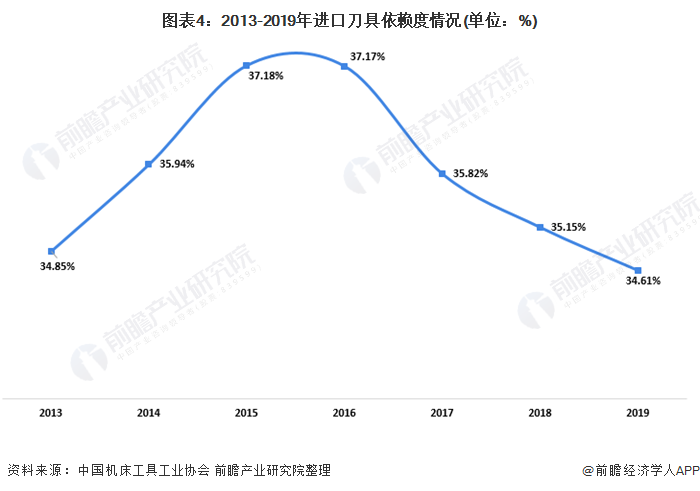

Import dependence is continuously decreasing

At present, the national economy has entered a new normal of medium-high speed growth, and the rising cost of production factors such as labor, raw materials, and energy has made it increasingly difficult for manufacturing enterprises to operate. "Reducing production costs and improving production efficiency" has become a consensus among many domestic manufacturing enterprises. In recent years, domestic cutting tool enterprises have rapidly risen, replacing some imported products with their cost-performance advantage and local service advantage, accelerating the domestic production of CNC cutting tools.

In 2019, the total consumption of cutting tools in China reached 39.3 billion yuan, of which the annual consumption of domestic cutting tools was about 25.7 billion yuan, and the annual consumption of imported cutting tools was about 13.6 billion yuan. Although domestic cutting tools account for 2/3 of the market share in total consumption and dominate the Chinese cutting tool consumption market, they are mainly low-end products. Among the 13.6 billion yuan of imported cutting tools, the vast majority are efficient cutting tools urgently needed by modern manufacturing industry. The ZTE communication incident has sounded an alarm for Chinese manufacturing, and the lack of key core technologies in key links will inevitably bind the vigorous development of China's high-end manufacturing industry. As CNC cutting tools, which are supporting tools for the high-end equipment manufacturing industry, accelerating their domestic production is of great significance to the security of the national economy. According to the statistical data of the China Machine Tool Tool Industry Association, the proportion of imported cutting tools in total consumption decreased from 37.17% to 34.61% from 2016 to 2019, which to some extent indicates that the self-sufficiency capacity of CNC cutting tools in China is gradually increasing, and the import dependence is decreasing year by year.

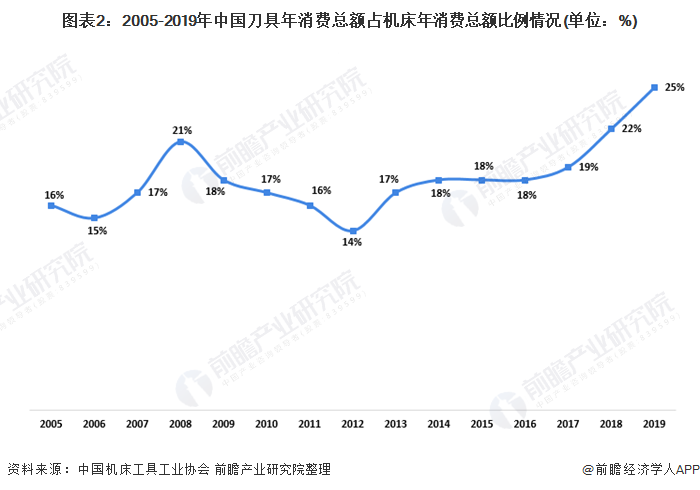

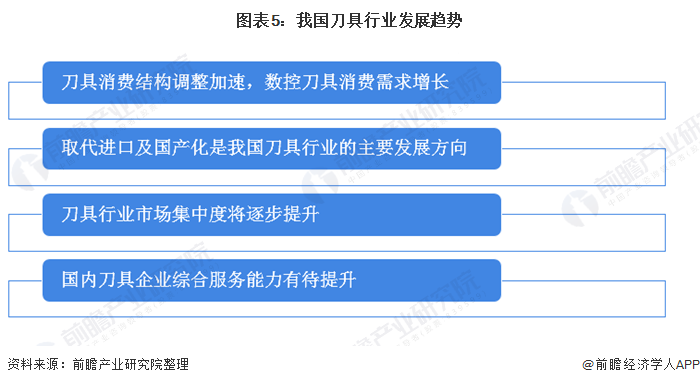

The future development trend of China's cutting tool industry will be as follows:

——The adjustment of cutting tool consumption structure is accelerating, and the demand for CNC cutting tools is growing. China is the country with the richest tungsten mine resources in the world, but the utilization level of tungsten resources is not high. There are many enterprises engaged in the production of hard alloy products and cutting tools in the whole country, but most of them are small in scale and mainly face the low-end market. With the advancement of China's industrial policy to extend hard alloy towards deep processing, the structure of hard alloy products and cutting tools is further optimized, and the proportion of deep processing products represented by CNC cutting blades will be further improved.

——Replacing imports and domestic production is the main development direction of China's cutting tool industry. During the "13th Five-Year Plan" period, China has put forward the "Made in China 2025" and "Internet Plus" action plans, promoting the upgrading of China's manufacturing industry towards automation and intelligence, and improving the level of digital manufacturing. CNC cutting tools are the components of digital manufacturing and the key means to improve labor productivity and quality, and they have the effect of "four liang to move a thousand jin" in saving manufacturing costs. The dependence on imported high-end CNC cutting tools is related to national economic security and national defense security, and it is a barrier to China becoming a manufacturing power.

At present, most of the cutting tool enterprises in China produce mid-low-end products mainly based on traditional standard cutting tools, and the supply of CNC cutting tool products that adapt to the development trend of digital manufacturing is insufficient. In recent years, China's cutting tool enterprises have made certain progress in the adjustment of product structure, and have replaced some imported products in some fields, but it is difficult for domestic cutting tools to replace imports in the short term.

——The market concentration of the cutting tool industry will gradually increase. In developed countries, cutting tools grow with digital manufacturing. With the improvement of the manufacturing industry's understanding, use and requirements for cutting tools, the upgrading of cutting tool materials from carbon tool steel, high-speed steel to hard alloy and superhard materials has taken place, and the cutting tool technology, R&D, marketing, service system is more complex than before, the imitation of cutting tools is becoming more and more difficult, the requirements for independent innovation are getting higher and higher, and the survival and development environment of small cutting tool enterprises is getting smaller and smaller. In the future, with the evolution of cutting tool technology, small enterprises do not have the ability to continue to invest in R&D in cutting tool materials, coating and other fields, and are at a disadvantage in market competition, and will inevitably be eliminated by the industry's leading enterprises.

At present, the cutting tool industry in our country is in a state of disorderly competition in the middle and low-end product market. A large number of small enterprises lack technological accumulation, have poor R&D capabilities and weak capital strength, and are facing the situation of being eliminated or acquired. Enterprises with brand, capital and technological advantages have a greater competitive advantage in the high-end application field, have a larger development space, and will obtain a larger market share, thus increasing the market concentration of the entire cutting tool industry.

——The comprehensive service capability of domestic cutting tool enterprises needs to be improved. At present, the internationally leading cutting tool production enterprises provide users with personalized cutting processing overall solutions with their rich product varieties, deep understanding of customer needs and high R&D capabilities. In the future, the role of cutting tool manufacturers in our country will change, expanding from simple cutting tool production and supply to the development of new cutting processes and corresponding supporting technologies and products, and from the status of a simple cutting tool supplier to an important partner to solve processing problems for user enterprises.

For more data, please refer to the "2020-2025 China Machining Tool Manufacturing Industry Production, Sales, Demand and Investment Forecast Analysis Report" by Precedent Industry Research Institute. At the same time, Precedent Industry Research Institute also provides industry big data, industry planning, industry declaration, industrial park planning, industry investment and recruitment and other solutions.

(Preceding Industry Research Institute)