Suzhou uses Pu Precision-Innovative WFP series drill bits, specially developed for processing automobile hub bearing units.

The wheel hub bearing unit is a critical safety component in the automotive chassis system, located at the center of the wheel and directly connecting the wheel and suspension system. It has four core functions:

Supporting load: bear the weight of the vehicle (radial load) as well as the lateral and axial loads generated during turning and braking.

Provide rotation: Ensure smooth and low friction rotation of the wheels relative to the axle or steering knuckle.

Transmitting torque: On the driving wheels, it is also necessary to transmit the driving torque of the engine/electric motor (for non driving wheels, it mainly bears the braking torque).

Integrated function: Modern HBUs typically integrate the target wheel (magnetic encoder or gear ring) and mounting surface of wheel speed sensors (used in ABS, ESP, TCS systems, etc.), and sometimes even directly integrate sensors.

▲Hub bearing unit

Given that the wheel hub bearing unit of a car is subjected to very large radial and axial loads during driving, its material not only needs to have high hardness and stronger wear resistance, but also high fatigue strength and good toughness. Common materials are S55C and 65Mn, which can reach a hardness of HB210-260 after high-temperature quenching and low-temperature tempering and heat treatment.

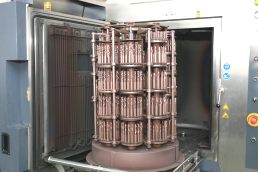

The bottom hole of the car wheel hub bearing unit requires very strict requirements during the machining process, with no scratches on the upper surface and no burrs at the outlet. At the same time, there are strict requirements for the hardening of the hole wall. These special and high requirements pose new challenges to the drilling bit for hole machining, which not only needs to reduce deformation and avoid inner hole hardening, but also needs to be durable and stable.

Suzhou Yongpu Precision has specially developed the WFP series wheel hub unit drill bits to meet this strict requirement!

It is tailor-made for the machining of bottom holes in automotive wheel hub bearing units, and is a reliable tool to overcome the difficulties of machining bottom holes in automotive wheel hub bearings.

The characteristics of using the Park Precision WFP series drill bits are as follows:

In terms of groove design:

Optimization of chip removal groove: excellent chip removal performance and wide chip storage space.

Special edge treatment: The edge strength is high, which improves the stability of the tool after grinding.

In terms of blade design:

Curved back blade: Provides high-strength blade support and higher blade safety.

Special design of the cutting edge: By adjusting the width of the cutting edge, the centering ability is improved while considering the strength of the cutting edge, reducing the axial force during drilling.

Curved cutting edge: The curved cutting edge ensures sharpness, reduces cutting resistance, and improves chip breaking performance.

Tip processing: Special tip processing to reduce the risk of hole wall work hardening

Detailed blade passivation:

Adjust and optimize the amount of blade passivation to reduce the risk of blade breakage.

Smooth blade passivation enhances tool wear resistance.

▲Special drill bit for WFP hub unit

Intelligent coating technology:

Low thermal conductivity, high wear resistance, can still maintain excellent performance in harsh working conditions.

▲Smart coating technology