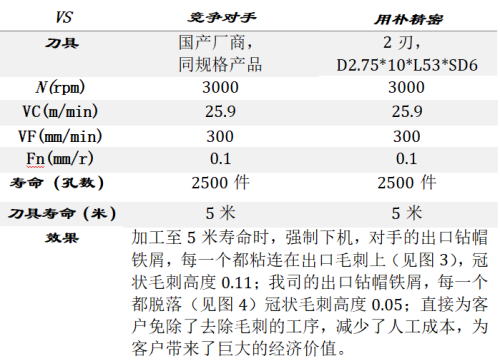

Case Background

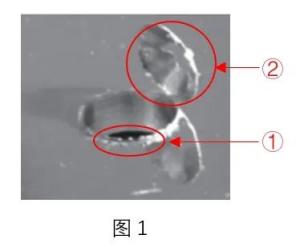

Have you ever encountered a lot of burrs at the exit of the hole after drilling? (See Figure 1) Even manual removal is impossible, causing you a lot of trouble and confusion? Yes, the burrs at the exit directly affect the accuracy, fatigue resistance, and assembly performance of the workpiece, and can also cause operators to get injured and accidents. Therefore, it is necessary to perform a secondary operation - deburring. Moreover, the secondary deburring and edge finishing of precision parts may account for 30% of the cost of the finished parts. In addition, it is difficult to automate deburring, and small burrs become a very difficult problem in metal processing.

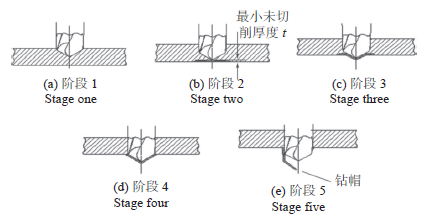

In response to this situation, Pu Precision has conducted an in-depth study of the mechanism of burr generation at the exit of drilling, and found that the exit burrs contain two parts, one part is the burr at the exit of the drilling cap, which is a circular cap-shaped chip generated in the final stage of drilling, adhering to the exit position, such as ② in Figure 1; the other part is the crown-shaped burr, which is a broken burr generated on the side of the machined hole, such as ① in Figure 1;

Application Case

Holes are machined on the airbag pipe, the workpiece material is 10MnCrNiMo alloy steel with a hardness of HRC38, machining through holes, hole depth of 2 mm, using MQL external cooling, since it is a pipe processing, the through hole is a round arc surface exit, which adds great difficulty to manually remove the exit burr, especially the burr of the drilling cap; but the use of the Puk precision suppression burr drilling bit successfully solves this problem.

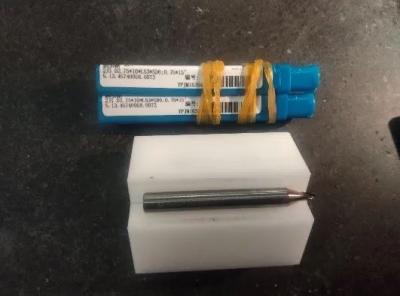

See below for cutting parameters and photos: